Why do we need carbon capture, use and storage?

While CO2 emissions from fuel combustion have been declining in Europe, industries like cement, iron and steel, aluminium, pulp and paper, and refineries have inherent CO2 emissions resulting from energy-intensive industry processes. Carbon capture, use and storage can provide a key contribution to tackling these sectors’ emissions. Furthermore, it can help removing carbon from the atmosphere through carbon removals such as bio-energy carbon capture and storage (BECCS) and direct air carbon capture and storage (DACCS) and be a platform for low-carbon hydrogen production.

On 15 December 2021, the Commission has published the Communication ‘Sustainable Carbon Cycles’, which sets the long-term objective to restore sustainable and climate-resilient carbon cycles.

The Commission’s strategic long-term vision depends in part on CO2 removal techniques based on CCS: either in combination with direct air capture (DACCS) or biomass (BECCS) to achieve climate neutrality. The target of climate neutrality has been written into law by the European Climate Law (Regulation (EU) 2021/1119), which requires that Union-wide greenhouse gas emissions (GHG) and removals are balanced within the Union at the latest by 2050 and that the Union shall aim to achieve negative emissions thereafter. Furthermore, several organisations and institutions such as the Intergovernmental Panel on Climate Change (IPCC), International Energy Agency (IEA) and National Energy Technology Laboratory (NETL) argue that without carbon removals it is difficult to keep the temperature levels indicated in the Paris agreement (explore the IPCC report).

How do CCS and CCU work?

The technological options envisaged in the 2050 long-term strategy and the ‘Sustainable Carbon Cycles’ Communication are the capture of carbon dioxide from the combustion of biomass or, as a last resort, fossil fuels, from industrial processes, and direct air capture. Capturing carbon dioxide directly from the atmosphere (DACCS) or from the combustion or fermentation of biogenic carbon (BECCS) has the potential to deliver negative emissions (carbon removals). The captured carbon is then either stored underground or used for the production of synthetic materials (fuels, chemicals, building materials).

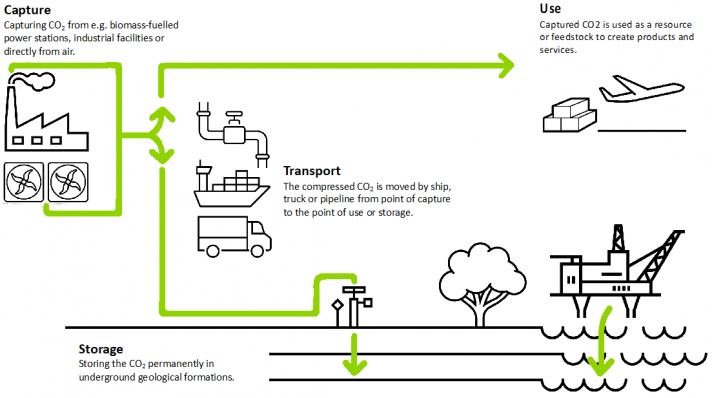

- 1) Capture: Capturing CO2 from e.g. biomass-fuelled power stations, industrial facilities or directly from air.

- 2) Transport: The compressed CO2 is moved by ship, truck or pipeline from point of capture to the point of use or storage.

- 3.a) Storage: Storing the CO2 permanently in underground geological formations.

- 3.b) Use: Captured CO2 is used as a resource or feedstock to create products and services.

Carbon Capture and Storage

Before carbon dioxide gas can be stored, it must be captured and stripped of most associated substances. This is not a new technology, as CO2 is routinely separated and captured as a by-product from industrial processes. The captured CO2 is then stored in compressed form and transported to the place of sequestration in tanks, pipelines or ships.

Carbon Capture and Utilisation

The utilisation of carbon dioxide in production processes refers to technologies and procedures, which use CO2 as a feedstock rather than releasing it to the atmosphere, e.g. by

- directly using CO2 in soft drinks or greenhouses,

- using it as a working fluid or solvent such as for enhanced oil recovery (EOR), or

- using CO2 as a feedstock and converting it into value-added products such as polymers, building materials, chemicals and synthetic fuels.

The latter family of novel technologies using CO2 as a feedstock may contribute to the circular economy and the climate mitigation objectives.

How is CO₂ transported?

Transport is the stage of carbon capture, utilisation or storage that links CO2 sources with production or storage sites. There are four basic options for transporting CO2: pipeline transport, waterborne transport, rail transport, and road transport.

In the context of long-distance movement of large quantities of CO2, pipeline transport is part of current practice. Pipelines routinely carry large volumes of natural gas, oil, condensate and water over distances of thousands of kilometers, both on land and in the sea. CO2 pipelines are not new: they extend over hundreds of kilometers worldwide. However, in Europe there are few CO2 pipelines today. Liquefied natural gas and petroleum gases such as propane and butane are routinely transported by marine tankers on a large scale. CO2 is transported in the same way, but on a small scale because of limited demand. Finally, liquefied gas can also be carried by rail and road tankers.

The challenges for a successful deployment of CO2 transport infrastructure are of economic and regulatory nature and often referred to as the chicken-and-egg problem. Due to the limited demand for CO2 to be stored in geological formations or incorporated into materials and fuels, there is a lack of incentive for CO2 emitters and potential direct air capture operators to capture CO2. Consequently, there is also no business case for operators of a potential CO2 infrastructure.

Integration of CCUS in high emission industrial hubs and clusters is expected to be the most cost-efficient approach. Sharing, eventually across borders, CO2 transport, use and/or storage infrastructure will help with achieving economies of scale, and improving the business case.

How safe is storing CO₂ underground?

The storage of CO2 in geological formations, including oil and gas reservoirs, unmendable coal seams, and deep saline reservoirs, is safe. The 2005 Special Report on CCS by the Intergovernmental Panel on Climate Change concluded that appropriately selected and managed geological reservoirs are 'very likely' to retain over 99% of the sequestered CO2 for longer than 100 years and 'likely' to retain 99% of it for longer than 1000 years. The site selection and safety assessment are ensured through the CCS Directive, which is the legal framework for safe geological storage of carbon dioxide in the EU and EEA countries.

Ensuring safe and environmentally sound CCS and CCU

The environmental integrity of CCS and CCU is the Commission's overriding concern.

For CCS, this is a matter of ensuring that the CO2 captured and stored remains isolated from the atmosphere in the long term; and a matter of ensuring that the capture, transport and storage elements do not present other risks to human health or ecosystems.

For this reason, the EU's CCS Directive provides a clear regulatory framework and guidelines for the safe geological storage of CO2. Before CCS projects receive any construction and operation permits, they need to conduct an Environmental Impact Assessment (EIA) addressing all environmental concerns, a detailed assessment of the site selection, and develop a monitoring plan addressing all possible leakage risks.

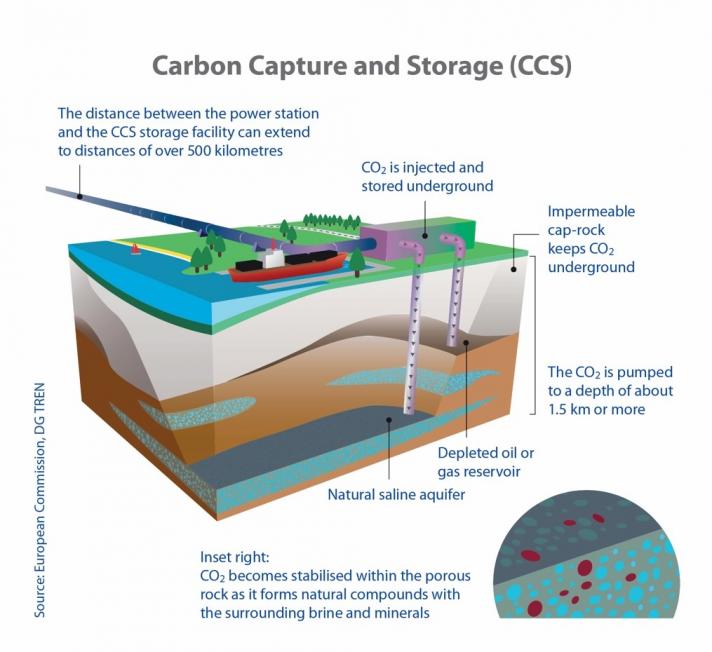

Carbon Capture and Storage (CCS). The distance between the power station and the CCS storage facility can extend to distances of over 500 kilometres

CO2 is injected and stored underground. The CO2 is pumped to a depth of about 1.5 km or more under an impermeable cap-rock into a depleted oil, gas reservoir or a natural saline aquifer

Inset right: CO2 becomes stabilised within the porous rock as it forms natural compounds with the surrounding brine and minerals

For CCU, it is a matter of better understanding the climate mitigation potential of the technologies by applying rigorous GHG emission reduction calculations such as for the Innovation Fund and adjusting the regulatory support accordingly, e.g. through the recast of the renewable energy directive, RED II.

The stakeholder event on carbon capture and utilisation technologies in 2018 informed about the GHG emission avoidance potential of these technologies and challenges ahead of them.

Barriers

Although the components of CCS and CCU are all known and deployed at a commercial scale, integrated systems are new. The capture component, in particular, is an expensive part of the process.

Large-scale CCS projects are currently in operation worldwide. However, some projects in planning have also been cancelled. The majority of these projects are slowed down by the lack of a robust business case, lengthy and complex implementation and lack of public acceptance and support. Some more barriers are mentioned below.

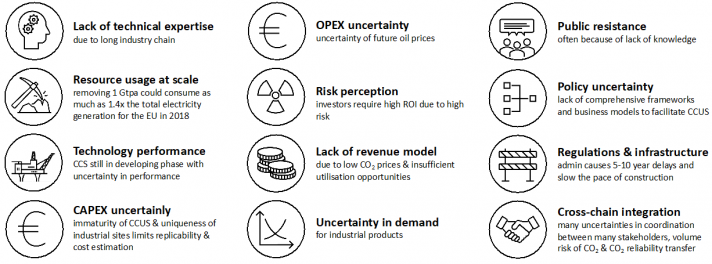

- Lack of technical expertise due to long industry chain

- Resource usage at scale: removing 1 Gtpa could consume as much as 1.4x the total electricity generation for the EU in 2018

- Technology performance: CCS still in developing phase with uncertainty in performance

- CAPEX uncertainly: immaturity of CCUS & uniqueness of industrial sites limits replicability & cost estimation

- OPEX uncertainty: uncertainty of future oil prices

- Risk perception: investors require high ROI due to high risk

- Lack of revenue model due to low CO2 prices & insufficient utilisation opportunities

- Uncertainty in demand for industrial products

- Public resistance: often because of lack of knowledge

- Policy uncertainty: lack of comprehensive frameworks and business models to facilitate CCUS

- Regulations & infrastructure: admin causes 5-10 year delays and slow the pace of construction

- Cross-chain integration: many uncertainties in coordination between many stakeholders, volume risk of CO, & CO, reliability transfer

Most novel CCU technologies are not yet commercialised. It is known that the large-scale expansion of CCU technologies will require large volumes of renewable energy and low-carbon hydrogen at competitive prices. Therefore, these developments will need to go hand in hand to reap the environmental and economic promise of CCU technologies.

EU funding for CCS and CCU

Several funding mechanisms for R&D and demonstration projects have been created via the research framework programmes and other EU funding mechanisms. Current EU funding schemes dedicated to supporting CCS and CCU are the following programmes:

- The Innovation Fund mobilises over EUR 25 billion, depending on the price of carbon, over ten years for breakthrough technologies in carbon capture, use and storage, as well as in renewable energy, energy-intensive industries, and energy storage.

- Connecting Europe Facility (CEF) supports cross-border CO2 transport networks.

- The Recovery and Resilience Facility (RRF) aims to mitigate the economic and social impact of the coronavirus pandemic through investments in flagship areas such as clean technologies and renewables, e.g. CCS and CCU.

- The Just Transition Fund (JTF) provides support to territories facing serious socio-economic challenges arising from the transition towards climate neutrality, i.a. support for CCS and CCU technologies.

- Horizon Europe supports research, pilots and small-scale demonstration projects related to carbon capture, utilisation and storage.

Legislation and policy initiatives in the EU

The Directive 2009/31/EC on the geological storage of CO2 (so-called "CCS Directive") establishes the overall legal framework for the environmentally safe geological storage of CO2 to contribute to the fight against climate change. The Commission works closely with competent authorities in Member States to ensure the implementation of the CCS Directive inter alia by facilitating exchanges, publishing guidance documents, and adopting Commission Opinions on draft storage permits.

As of 2021, the recast of the Renewable Energy Directive will encourage fuels produced by CCU. This element has been also been strengthened with the legislative package to deliver the European Green Deal. Besides the proposal for a revised Renewable Energy Directive, the Commission has also proposed the ReFuelEU Aviation Initiative that will oblige fuel suppliers to blend increasing levels of sustainable aviation fuels in jet fuel taken on-board at EU airports, including synthetic low carbon fuels, known as e-fuels.

In addition to this, the Commission is investigating the possibility to develop an EU certification system for carbon removals. On 15 December 2021, the Commission published the Communication ‘Sustainable Carbon Cycles’, which sets out an action plan on how to develop sustainable solutions to increase carbon removals.

In the next few years, we need to scale up carbon removals, be it in the land sector or in industry. Improving the monitoring, reporting and verification is the first fundamental step to enable robust markets and regulatory uses of carbon certificates. Carbon farming and industrial projects that invest in carbon removals today should have a prospect of a future robust accounting and certification framework that ensures comparability and recognition of the action started already on the ground.

To this end the Commission will propose a regulatory EU framework for the certification of carbon removals [link to Roadmap or Call for Evidence] by the end of 2022. The certification framework should ensure the transparent identification of carbon farming and industrial solutions that unambiguously remove carbon from the atmosphere.

Furthermore, the Strategic Energy Technology (SET) Plan TWG9 identifies Research and Innovation (R&I) priorities for CCS and CCU. This serves as a guideline for Member States, research institutes, and companies to focus on bringing these low-carbon technologies to the market faster and in a cost-competitive way.

Further regional opportunities

- 31/10/2019 - COM(2019) 566 - Report on the implementation of Directive 2009/31/EC on the geological storage of carbon dioxide

- 01/02/2017 – COM(2017) 37 - Report on the implementation of Directive 2009/31/EC on the geological storage of carbon dioxide- Annex

- 25/02/2014 - COM(2014) 99 - Report on the implementation of Directive 2009/31/EC on the geological storage of carbon dioxide

- 27/3/2013 – COM(2013) 180 - Consultative Communication on the future of Carbon Capture and Storage in Europe

- 27/3/2013 – MEMO/13/276 – Consultative Communication on the future of Carbon Capture and Storage in Europe

- 08/06/2010 – Monitoring and reporting guidelines on CCS under the EU ETS Directive

- 10/01/2007 – COM(2007) 843 - Communication on sustainable power generation from fossil fuels: aiming for near-zero emissions from coal after 2020

- Intergovernmental Panel on Climate Change special report on carbon dioxide capture and storage

FAQ

Questions and Answers on the geological storage and utilisation of carbon dioxide (Status: December 2021)

Carbon removal technologies are key to reaching the EU 2050 climate targets as renewable technologies only will not be sufficient.

While energy efficiency and renewables are in the long term the most sustainable solutions both for the security of supply and climate change mitigation, global greenhouse gas emissions cannot be reduced as they need to be to reach the Paris Agreement objective, if we do not also use other options such as carbon capture, utilisation and storage.

Timing is crucial. About a third of existing coal-fired power capacity in Europe will be replaced within the next 10 years. However, internationally, the energy consumption of China, India, Brazil, South Africa and Mexico will lead to a major global demand increase, which is likely to be met in large part from fossil fuels. The capacity to deal with these very substantial potential emissions must urgently be developed.

Carbon capture and storage (CCS) is a combination of technologies that capture CO2 and then safely stored it underground in suitable geological formations.

Carbon capture and storage is a suite of technological processes which involve capturing carbon dioxide (CO2) from the gases discarded by industry and transporting and injecting it into geological formations.

CCS can be applied to biomass or fossil fuel power plants and CO2-intensive industries such as cement, iron and steel, petrochemicals, oil and gas processing and others. After capture, the CO2 is transported to a suitable geological formation where it is injected, with the aim of isolating it from the atmosphere for good.

There are storage options other than geological storage, such as storage in the water column and mineral storage. Storage in the water column is considered to present a high environmental risk and the directive on the geological storage of CO2 bans it within the Union.

An option to capture CO2 is to take it directly from the air, which is called direct air capture (DAC). The main challenge in this process is that the concentration of CO2 in the ambient air is rather low (around 400ppm). The advantage of direct air capture is that it allows capturing CO2 when and where there are no point sources. DAC uses engineering processes relying on chemical capture to remove carbon dioxide (CO2) directly from the atmosphere into a separating agent that is regenerated with heat, water, or both. The CO2 is subsequently desorbed from the agent and released as a high purity stream. The combination of DAC and CCS is called DACCS and has the potential to deliver carbon removals.

BECCS (bio-energy carbon capture and storage) is the combination of generating energy from biomass and carbon capture and storage. Apart from the feedstock being specifically bio-based, the technologies deployed for capturing, transporting and storing the CO2 are the same as for CCS. The CO2 for BECCS can stem from biological processes such as fermentation (e.g. for the production of biofuels) but also from the combustion of biomass for the generation of heat and power. BECCS has the potential to deliver carbon removals.

Carbon capture and utilisation (CCU) is a process where the captured CO2 is used as a resource to create valuable products.

The utilisation of carbon dioxide in production processes refers to technologies and procedures, which use CO2 as a feedstock rather than releasing it to the atmosphere. The large-scale expansion of CCU technologies will require large volumes of renewable energy and low-carbon hydrogen at competitive prices. It is essential that research and development improve the efficiency of using renewable energy to produce CCU products.

The Commission is committed to addressing CCU in the wider context of establishing an EU regulatory framework on carbon removals, which it will propose by the end of 2022. The Commission will explore the development of a regulatory framework for the certification of carbon removals based on robust and transparent carbon accounting to monitor and verify the authenticity of carbon removals, in order to incentivise the uptake of carbon removal and increased circularity of carbon, in full respect of the biodiversity objectives.

In order to avoid a rebound effect, where the captured CO2 in products is emitted back into the atmosphere, CCU products should substitute similar products on the market made from fossil feedstock.

Large quantities of CO2 are already consumed through reaction with ammonia to produce urea, a key ingredient in fertilisers. This is an established and commercially viable technology that already produces the annual global supplies of urea, and is therefore a saturated market. Similarly, CO2 is used in the production of soda drinks and beer. However, CO2 is immediately released into the atmosphere when these products are used.

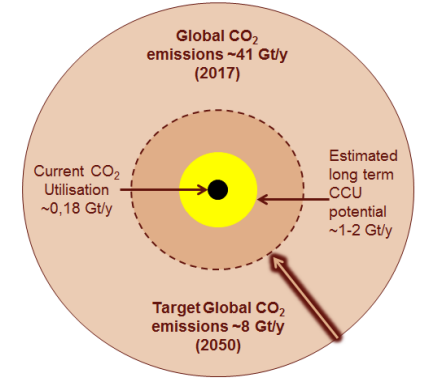

The further climate mitigation potential of CCU products depends on the substitution of similar products on the market made from fossil feedstock. Otherwise CCU products would simply create a rebound effect with more material use and CO2 emissions. Novel CCU applications are studied such as using CO2 as a feedstock and convert it into polymers, building materials, chemicals and synthetic fuels. The market for all possible CO2 utilisation options is several orders of magnitude smaller than the amount of CO2 released into the atmosphere each year from anthropogenic sources, see figure below from the EC Chief Scientific Advisors on Novel carbon capture and utilisation technologies.

The separate elements of capture, transport and storage of CO2 have all been demonstrated, but integrating them into a complete process and bringing costs down remain a challenge. Most novel CCU technologies are not yet commercialised.

The only two commercial CO2 storage projects are the Sleipner project in the North Sea and the Snøhvit project in the Barents Sea, both by Equinor. Both projects involve stripping CO2 from natural gas – a process which is already carried out before the gas can be sold – and storing it in underground geological formations. The two projects were spurred on by the Norwegian tax on CO2 which was significantly higher than the cost per tonne of CO2 stored in the geological formations.

CCU technologies on the other hand only exist on pilot scale. The large-scale expansion of CCU technologies will require large volumes of renewable energy and low-carbon hydrogen at competitive prices. Therefore, these developments will need to go hand in hand to reap the environmental and economic promise of CCU technologies.

The ZEP Platform The European Zero Emissions Technology & Innovation Platform, a stakeholder initiative supported by the Commission, has identified many full-scale demonstration projects that could go ahead once the necessary economic framework is in place, such as for Porthos and Northern Lights.

Carbon capture utilisation and storage is not economical due to its high costs and lacking business model.

The cost of CCS and CCU involves partly capital investment on equipment to capture, utilise, transport or store CO2, and partly the cost of operating this equipment to utilise or store the CO2 in practice, such as the amount of energy required to capture, transport and convert or inject the CO2. At current technology prices, upfront investment and operating costs are about 30 to 70 % (i.e. several hundred million euros per plant) greater than for standard plants. The high variation is due to the cost dependence on carbon source, location and transportation mode. The costs for carbon capture and utilisation are even higher because of complex conversion processes.

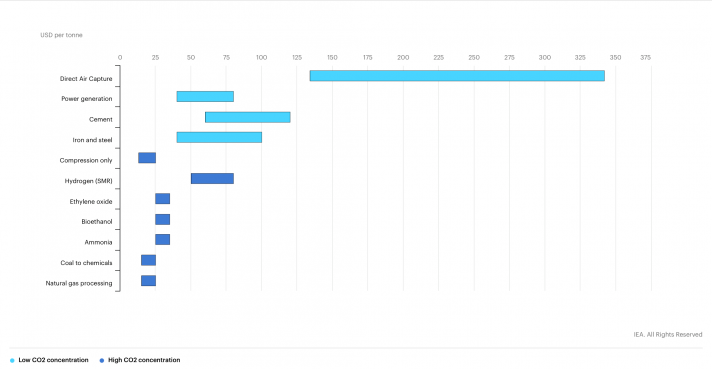

The capture component, in particular, is an expensive part of the process, as illustrated in the figure below. E.g. flue gas from coal or gas-fired power plants contains relatively low concentrations of CO2 (10-12% for coal and around 3-6% for gas). The subsequent amount of energy needed to capture the gas makes the process costly. Therefore, the cost remains an important barrier to the take-up of carbon capture. However, higher concentration of CO2 in some industrial flue gas streams, advancements in research for new capture technologies, and learning from demonstration plants will reduce costs of carbon capture in the future.

IEA, Levelised cost of CO2 capture by sector and initial CO2 concentration, 2019, IEA, Paris https://www.iea.org/data-and-statistics/charts/levelised-cost-of-co2-capture-by-sector-and-initial-co2-concentration-2019

CCS costs can be covered currently partly through the EU Emissions Trading Scheme (ETS) and partly through private and public funding. Currently, the ETS does not reward CCU due to lack of evidence and methodologies.

In the early phase, CCS demonstration projects will require additional finance on top of the incentive provided by the carbon market because the current cost of the technology is substantially higher than the carbon price. To catalyse this additional finance, decisive financial commitment from industry will be crucial and Member State support measures play a major role.

The costs of CCS are expected to decrease once there are a number of operational large-scale demonstration plants. With the strengthened carbon signal due to the increased 2030 and 2050 climate ambition, it should become cheaper to apply CCS rather than to release CO2 in the atmosphere.

On the other hand, CCU is solely relying on private and public funding. The Commission is investigating the possibility to develop an EU certification system for carbon removals, which may also cover certain CCS and CCU applications not currently supported by existing legislation, such as CCS in combination with biomass, direct air capture or CCU building materials.

CCS is supported through the Emission Trading Directive and the CCS Directive, as well as through funding schemes. As of 2021, the recast of the Renewable Energy Directive will encourage fuels produced by CCU.

In view of the importance of early demonstration of CCS and given that a number of projects may require some public funding, the Environmental State Aid Guidelines enable the use of State aid.

The Emission Trading Directive foresees that Member States should use at least 50% of their auctioning revenues to finance the fight against climate change. In addition, from 2020 to 2030, 450 million EU allowances as well as any unspent funds from the NER300 programme will be made available under the Innovation Fund to support low-carbon technologies, including CCS and CCU. Furthermore, as of 2021, the recast of the Renewable Energy Directive will encourage fuels produced by CCU.

CO2 captured and stored will not considered as “emitted” under the ETS.

The ETS provides the main incentive for CCS deployment. According to the EU legal framework, CO2 that is captured and safely stored is considered as “not emitted” under the ETS. Since the 2015 amendment to the Emissions Trading Directive, capture, transport and storage installations are explicitly included in the ETS.

No.

It is up to each operator to decide whether it makes commercial sense to deploy CCS or CCU, depending on the carbon price, the price for green products and the cost of the technology. The CCS Directive enables carbon capture and storage by providing a framework to manage environmental risks and remove existing legislation barriers. There is no specific EU legislation for CCU.

The CO2 can be geologically stored by trapping it in rock formations, by dissolving it in water found in geological formations or through chemical reactions with rock formations to minerals.

There are four main mechanisms to trap CO2 in geological formations.

- Structural trapping, which is the presence of an impermeable cap-rock which prevents CO2 from escaping from the outset.

- Residual CO2 trapping, where CO2 is trapped by capillary forces in the interstices of the rock formation, which develops about 10 years after injection.

- Solubility trapping, where the CO2 dissolves in the water found in the geological formation and sinks because CO2 dissolved in water is heavier than normal water. This becomes important between 10 and 100 years after injection.

- Mineral trapping happens when dissolved CO2 chemically reacts with the rock formation to produce minerals.

Typical sites are depleted oil and gas fields and saline aquifers. The permitting procedure includes a two-step review by the Member State authority and the Commission.

The two main geological formations that can be used for CO2 storage are depleted oil and gas fields, and saline aquifers (groundwater bodies whose salt content makes them unsuitable for drinking water or agriculture).

Site selection is the crucial stage in designing a storage project. Member States have the right to determine which areas of their territory are free to be used for CO2 storage. When exploration is required to generate the necessary information, exploration permits must be issued on a non-discriminatory basis, valid for two years with the possibility of extension.

A detailed analysis of the potential site must be carried out according to criteria specified in Annex I of the CCS directive, including modelling the expected behaviour of CO2 following injection. The site can be only used if this analysis shows that under the proposed conditions of use there is no significant risk of leakage, and that no significant health or environmental impacts are likely to occur.

The initial analysis of the site is done by the potential operator, who then submits the documentation to the Member State competent authority in the permit application. The competent authority reviews the information and if it is satisfied that the condition is met, issues a draft permit decision.

For the early storage projects, the directive includes an additional safeguard. To ensure consistent application of the directive across Europe and promote public confidence in carbon capture and storage the draft permits are reviewed by the Commission. The Commission's opinion is public (see here or here), but the final permitting decision remains with the national competent authority according to the subsidiarity principle.

In 2020, Europe reached 1/10.000th of its total capacity, thus a lot of storage is still available. Once the storage sites are filled, they are closed and monitored.

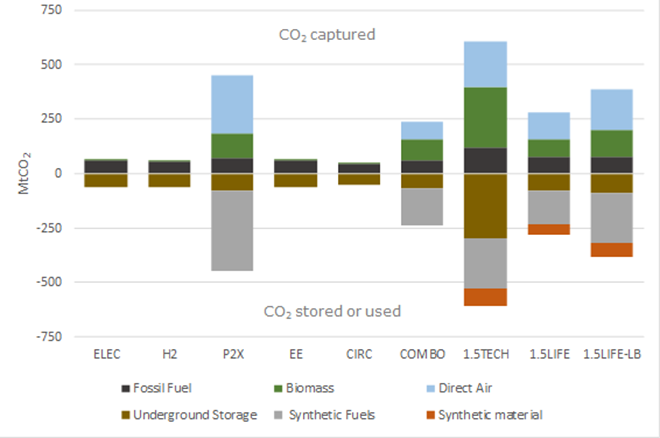

The capacity per storage sites varies. In Europe, we have 300 GtCO2 storage reservoirs available, of which until 2020 only 35.4 MtCO2 was used. According to the in-depth assessment for the Clean Planet for All Communication, we would need between 201 and 606 of MtCO2 storage per year in 2050 to reach EU climate neutrality objective, as shown in the figure below. Once the storage sites are filled, they are closed and monitored.

The EU regulations on storage are limited within the EU and EEA.

The directive can only regulate storage within the European Union and the European Economic Area. If the CO2 that is stored in these regions is in accordance with the directive, then the emitted CO2 will be considered as “not having been emitted” under the ETS. Storing CO2 emissions outside the European Union is not banned but any emissions stored as such will not receive any credits under the ETS, providing little incentive to store carbon dioxide abroad.

The probability of leakage at appropriately selected and managed storage sites is minimal.

The risk of leakage depends on the site in question. The IPCC Special Report on CCS concluded that the fraction of CO2 retained in appropriately selected and managed geological reservoirs is very likely to exceed 99% over 100 years and likely to exceed 99% over 1000 years. In other words, the probability of leakage at appropriately selected and managed storage sites is minimal.

The requirements for on-site selection are designed to ensure that only sites with minimal risk of leakage are chosen. The review of draft permit decisions by the Commission provides additional confidence that the requirements will be implemented consistently across the EU. Besides, the operators are required to set up a monitoring plan to verify that the injected CO2 is behaving as expected.

According measures need to be taken to return the site to a safe state. The leaked CO2 will be subtracted from the Emissions Trading Allowances.

If, despite the precautions taken in selecting a site, the site does leak in practice, corrective measures must be taken to rectify the situation and return the site to a safe state. Emissions Trading Allowances must be surrendered for any leaked CO2, to compensate for the fact that the stored emissions were credited under the ETS as not emitted when they left the source. Finally, the requirements of the Environmental Liability Directive on repairing local damage to the environment will apply in the case of leakage.

The Member State authority is responsible for carrying out routine annual inspections.

The competent authority in the Member States must ensure that inspections are carried out to verify that the provisions of the directive are observed. Routine inspections must be carried out at least once a year, involving the examination of the injection and monitoring facilities and the full range of environmental effects from the storage complex. Besides, non-routine inspections must be carried out if any leakage has been notified or if the operator's annual report to the competent authority shows that the installation is not compliant with the directive.

After injection finishes as planned, the site is closed and the post-closure monitoring period commences. After 20 years or less, if the site is stable, the private operator can request transfer of responsibility to the state.

Geological storage will extend over much longer periods than the lifespan of an average commercial entity. Arrangements are needed to ensure the long-term stewardship of storage sites. The directive allows the responsibility of the site to be transferred to Member State control in the long term. However, the polluter pays principle requires that the operator retain responsibility for a site while it presents a significant risk of leakage. Also, rules are needed to ensure that no distortion of competition arises from different Member State approaches.

Under the directive a storage site shall be transferred to the state when

- all available evidence indicates that the CO2 will be completely contained for the indefinite future,

- a minimum period before transfer to be determined by the competent authority has elapsed,

- a financial contribution for the post-transfer period covering at least the costs for monitoring for 30 years has been made, and

- the site has been sealed and the injection facilities have been removed.

As this is the second key decision in the lifecycle of a storage site (the first being the decision to permit the site for use), a Commission review is foreseen at this stage, too.