Industrial Carbon Management (ICM) refers to a range of technologies used to:

- manage and reduce carbon dioxide (CO2) emissions from industrial facilities;

- remove CO2 from the atmosphere.

The European Commission is supporting the deployment of ICM technologies throughout Europe and the creation of a single European market for CO2. This includes creating a harmonised policy framework that encourages more investment in ICM solutions.

Why do we need Industrial Carbon Management?

ICM technologies are key to reaching the EU’s 2050 climate neutrality target and contributing to the goals set by the Paris Agreement. Based on the modelling used in the Communication on Europe’s 2040 climate target, fossil fuel consumption in the EU will fall heavily by 2040. This decrease will be achieved through the deployment of renewable energy sources and the implementation of principles such as circularity and resource efficiency, as well as the use of alternative production processes and material substitution.

Fossil fuel consumption will decline even further thanks to the latest reform of the EU Emissions Trading System (ETS), through which industrial emissions in the EU must now decline at a faster pace. ICM solutions can contribute to the mitigation of greenhouse gas (GHG) emissions and help decarbonise production processes in key European industrial sectors.

CO2 emissions from fuel combustion are on a declining trend in the EU. However, emissions from energy-intensive industries that are critical for our economy and quality of life - such as cement, iron and steel, aluminium, pulp and paper and refineries - remain steady. To achieve its full economic potential while reaching climate neutrality by 2050, the EU will need to significantly scale up efforts and tackle emissions in these hard-to-abate sectors.

According to existing policies, at least 50 million tonnes of CO2 per year must be stored underground in Europe by 2030. Moreover, according to modelling used in the EU’s 2040 climate target Communication, some 280 million tonnes would need to be captured by 2040 and around 450 million tonnes by mid-century.

CO2 can be captured, preventing it from being released into the atmosphere, and then either stored or used. These practices are known as Carbon Capture and Storage (CCS) and Carbon Capture and Utilisation (CCU). Most of the captured CO2 involved in CCS and CCU comes from industrial processes or fossil fuel combustion (e.g., in a coal power station).

Captured CO2 can also have a biogenic or atmospheric origin. Biogenic CO2 is produced through biological processes (e.g., in biomass power plants or waste-to-energy plants), while atmospheric CO2 is found naturally in the atmosphere. Capturing and permanently storing CO2 of biogenic or atmospheric origin is a practice known as carbon removals.

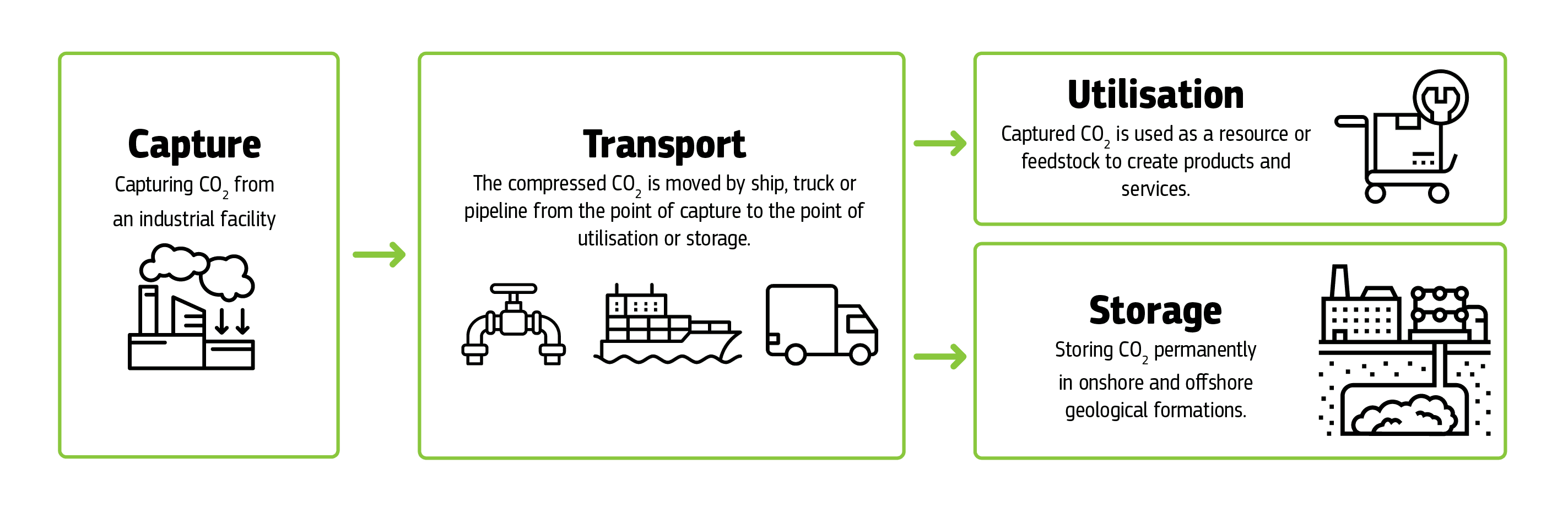

Once captured, as illustrated below, CO2 is transported to its utilisation or storage location.

The image shows a process flow diagram of Carbon Capture, Utilization and Storage (CCUS) technology.

- Capture: Capturing CO2 from an industrial facility. An image is shown of CO2 emissions being captured from an industrial facility.

- Transport: The compressed CO2 is moved by ship, truck or pipeline from the point of capture to the point of utilisation or storage. An image of a pipeline, a ship and a truck is shown.

- Utilisation: Captured CO2 is used as a resource or feedstock to create products and services. An image of a handcart with a box and a wrench is shown.

- Storage: Storing CO2 permanently in onshore and offshore geological formations. An image of a factory and a geological formation with stored CO2 is shown.

How does Carbon Capture and Storage work?

Carbon Capture and Storage (CCS) is a combination of technologies used to capture CO2 from industrial exhaust gases and safely store it underground in suitable geological formations.

Before CO2 can be transported and injected into geological formations, it must be filtered to remove any unwanted substances. This is not a new technology, as CO2 is routinely separated and captured as a by-product from industrial processes. The captured CO2 is then compressed or liquified and transported to its final storage location using tanks, pipelines or ships. Captured CO2 can also be used to produce synthetic materials (such as fuels, chemicals, or building materials).

CCS technologies can be used in biomass or fossil fuel power plants, as well as in carbon-intensive industries such as cement, iron and steel, petrochemicals, oil and gas processing, and others. Once captured, CO2 can be transported to a suitable geological formation where it is injected with the aim of preventing emissions from being released into the atmosphere.

Carbon removal solutions such as Bio-Energy Carbon Capture and Storage (BECCS) combine energy generation from biomass and CCS. Apart from the feedstock being specifically bio-based, the technologies deployed for bio-energy carbon capture and storage are the same used for CCS. The CO2 used in BECCS can be generated by biological processes such as fermentation (e.g. to produce biofuels), as well as by biomass combustion for heat and power generation.

Another carbon removal solution based on CCS is Direct Air Carbon Capture and Storage (DACCS). In this case, CO2 is captured directly from ambient air and permanently stored underground. Capturing significant amounts of CO2 through DACCS can be challenging. This is because the concentration of CO2 in ambient air is much lower than in industrial sources where carbon capture techniques are usually applied.

Read more about what the European Commission is doing to remove CO2 from the atmosphere.

How does Carbon Capture and Utilisation work?

In Carbon Capture and Utilisation (CCU), captured CO2 is used to create valuable products. The term “utilisation” refers to production technologies and processes which use CO2 as a feedstock rather than releasing it to the atmosphere.

Carbon utilisation processes include:

- Using CO2 directly (e.g., in greenhouses)

- Using CO2 as a working fluid or solvent (e.g., in enhanced oil recovery)

- Using CO2 as feedstock by converting it into value-added products such as polymers, building materials, chemicals, and synthetic fuels.

For example, large quantities of CO2 are already consumed through a reaction with ammonia to produce urea, a key ingredient in fertilisers. This is an established and commercially viable technology that already contributes to the annual global supplies of urea.

However, when these kinds of products are used, CO2 is immediately released into the atmosphere. Therefore, the full climate mitigation potential of CCU products can only be exploited if they replace similar products made from fossil feedstock on the market. If this does not happen, CCU products would simply create a rebound effect with more material use and additional CO2 emissions.

How can CO₂ be transported?

There are four existing options for transporting CO2:

- Pipeline

- Maritime transport

- Rail

- Road

If large quantities of CO2 must travel a long distance, the most common option is pipeline transport. Pipelines regularly carry large volumes of natural gas, oil, condensate and water for thousands of kilometres, both on land and at sea. CO2 pipelines are not new: they extend over hundreds of kilometres worldwide and allow CO2 to be transported in either liquefied or gaseous form. However, there are currently only a few CO2 pipelines in Europe.

Maritime transport, using marine tankers, is generally used to transport liquefied natural gas and petroleum gases such as propane and butane. CO2 is transported similarly, but on a smaller scale, due to limited demand. Transport of CO2 by truck and rail is possible for small quantities and short distances, especially when CO2 is captured from a facility located far from a pipeline transport network, or in remote areas (e.g. on a mountain or in a forest).

How can CO₂ be stored underground?

CO2 can be stored geologically by trapping it in rock formations, dissolving it in water found in geological formations, or inducing chemical reactions with rock formations to produce minerals. There are four main mechanisms to trap CO2 in geological formations:

- Structural trapping, where the presence of an impermeable cap-rock prevents CO2 from escaping in the first place.

- Residual CO2 trapping, where CO2 gets trapped by capillary forces which develop in the interstices of a rock formation about 10 years after CO2 is injected.

- Solubility trapping, where the CO2 dissolves in the water found in the geological formation and sinks deeper underground as water containing dissolved CO2 is heavier than normal water. This process occurs after between 10 and 100 years after injection.

- Mineral trapping happens when dissolved CO2 reacts chemically with a rock formation to produce minerals.

The storage of CO2 in geological formations, including depleted oil and gas fields, unmendable coal seams, basalt rocks and deep saline aquifers, is safe for people and the environment. The Commission ensures careful site selection and safety assessment through the CCS Directive, which provides the legal framework for the safe geological storage of CO2 in EU and European Economic Area (EEA) countries. Discover how the Commission is ensuring the safety of CCS in Europe in our dedicated brochure available in all EU languages.